WE DON'T INVENT THE WHEEL. WE REPAIR IT !!!Our company “KT Servis” has more than 15 years experience in designing, manufacturing and delivering of the equipment for the maintaining of any heavy quarry machinery: for such trucks as BelAZ dumpers, CATERPILLAR, KOMATSU, HITACHI, EUCLID, VOLVO, TEREX, quarry loaders, wheeled tractors, agricultural and other wheeled machinery. Geographical position of our companyHead office “KT Servis” is situated in the industrial region of Russia - Ural. Due to our location we can easily deliver our equipment across all over the Russian Federation. We offer the following Russian-made products: 3. OTR Tyre Changing Press ( OTR Tyre demounting and mounting machine) QualityAll our machinery is produced on high technology equipment. We use only high quality European accessories. The quality of our products is confirmed by 10 years work and by more than 150 customers in Russia, Ukraine, Kazakstan, Armenia and Belorussia. Our clients are first-rate companies in the field of coal mining industry, in iron ore and non-ferrous ore mining, in mining of diamonds, bauxites, crushed stone etc.

1. Earthmover Tyre Repair System (OTR repair system)1.1. Vulcanizing Machine «Model 33.00»

The GIANT Model 33.00 vulcanization machine is designed to repair OTR tires from 25" to 57". It uses a two-stage system for repairing local damage to giant tires: hot vulcanization of the damage funnel and a sticker of the repair patch with cold vulcanization. It is an excellent replacement for REMA TIP TOP vulcanizer EM 2. It has been produced in Russia since 2001. During this time, more than 50 vulcanization machines were sold. Moreover, the first is still working.

Machine guidelines

1.2. Vulcanizing System «Model 63»

Vulcanizing System Vulcanizing System "Model 63" consist from: vulcanizer for repair of tires 49"-63" and EM repare stand (loading capacity 7500 kg).

1.3. Vulcanizing Machine «Model 40.00»

Based on this Vulcanizing Machine the delivery of full set of OTR repair equipment including all necessary equipment, instrument and expendables for repair actions is possible. 1.4. Vulcanizing Machine «Model 21.00»

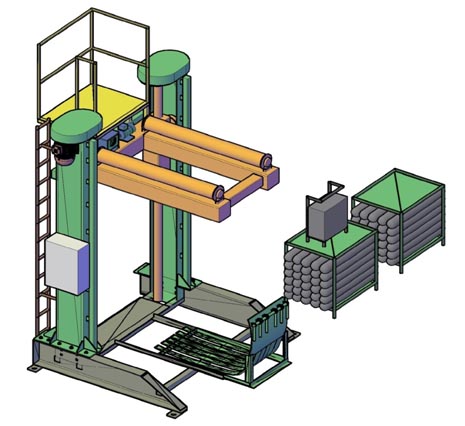

Based on this Vulcanizing Machine the delivery of full set of OTR repair equipment including all necessary equipment, instrument and expendables for repair actions is possible. 2. EM repair standFor easy handling of EM tyres during the repair process Speeds up the positioning of the tyre in the EM machine and improves safety at work 2.1. Мodel 06030Designed for the handling of large tyres. The tyre is lifted by a powerful electromechanical system. The rollers on which the tyre is positioned are driven electrically. |

| 1 | Name | OTR repair stand, code 06030 |

| 2 | Tyre size |

range 27.00-49 through 40.00-57 |

| 3 | Type of post | Fixed, symmetrical |

| 4 | Type of drive | Electromechanical winding |

| 5 | Maximum carrying capacity | under 4500kg |

| 6 | Maximum height of track rollers lift |

2690mm |

| 7 | Minimum height of track rollers lift |

1190mm |

| 8 | Voltage | 380V |

| 9 | Weight | 800kg |

| 10 | Overall dimensions | 1800х1800х3000 mm |

![]() Download specification Cod. 06030

Download specification Cod. 06030

2.2. Моdel 06035

Designed for the handling of large tyres. With an electric drive of spinning rollers and a hand drive of the vertical carriage movement.

Designed for the handling of large tyres. With an electric drive of spinning rollers and a hand drive of the vertical carriage movement.

| 1 |

Name |

OTR repair stand, code 06035 |

| 2 |

Tyre size |

range 27.00-49 through 40.00-57 |

| 3 |

Type of post | Fixed, symmetrical |

| 4 |

Type of drive | Electromechanical |

| 5 |

Maximum carrying capacity | under 4500kg |

| 6 |

Maximum height of track rollers lift |

2690mm |

| 7 |

Minimum height of track rollers lift |

1190mm |

| 8 |

Voltage | 380V |

| 9 |

Weight | 600kg |

| 10 |

Overall dimensions | 1800х1800х3000 mm |

![]() Download specification Cod. 06035

Download specification Cod. 06035

2.3. Моdel 06026

Total access to the tyre

Total access to the tyre

Working height of the tyre is adjusted by specially geared hand crank

The roller bars allow easy rotation to the desired position and eliminate the risk of damage to the bead area

Castors enable convenient movement

| 1 | Name | OTR repair stand, code 06026 |

| 2 | Tyre size | range 18.00-25 through 27.00-49 |

| 3 | Maximum tyre diameter |

2700 mm |

| 4 | Maximum tyre width | 1000 mm |

| 5 | Carrying capacity | under 2000 kg |

| 6 | Weight | 320 kg |

| 7 | Overall dimensions | 1400х1700х2150 mm |

2.4. Моdel 06020

Total access to the tyre

Total access to the tyre

Working height of the tyre is adjusted by specially geared hand crank

The roller bars allow easy rotation to the desired position and eliminate the risk of damage to the bead area

Castors enable convenient movement

| 1 | Name | OTR repair stand, code 06020 |

| 2 | Tyre size | range 18.00-25 through 21.00-35 (exclude 35/65-33) |

| 3 | Maximum tyre diameter |

2200 mm |

| 4 | Maximum tyre width | 760 mm |

| 5 | Carrying capacity | under 800 kg |

| 6 | Weight | 190 kg |

| 7 | Overall dimensions | 1100х1220х1950 mm |

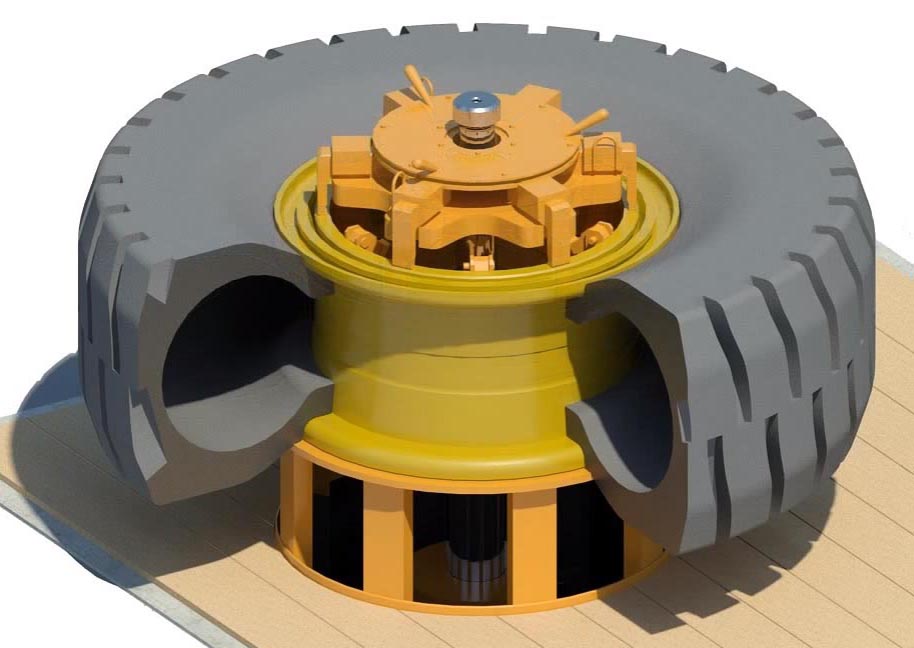

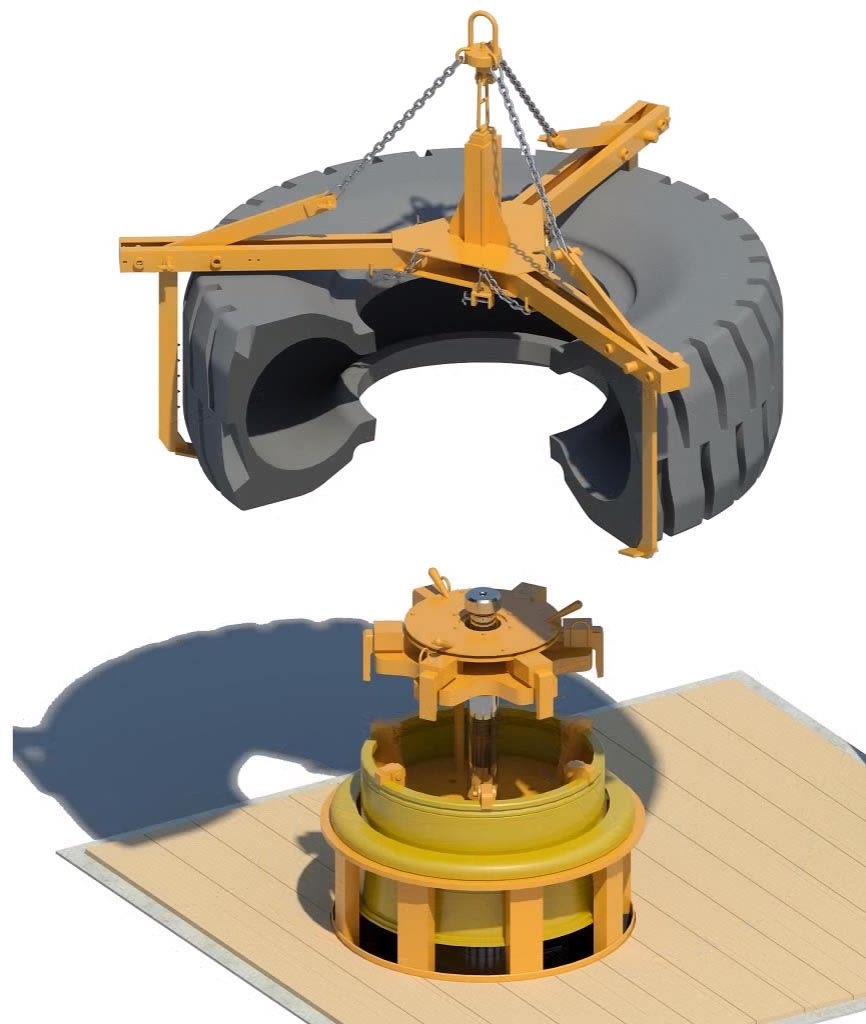

3. OTR Tyre Changing Press (OTR Tyre demounting and mounting machine)

For safely and quickly mount/dismount/inflate Giant or Off The Road (OTR) tire assemblies

3.1. Portable OTR tyre changers

Mobile OTR tyre changers SHM series is analogue of MTM tyre changers manufactured by Maruma Technica co. ltd., Japan.

Specification

| Model | SHM-70 | SHM-100 | SHM-150 |

| For all tyres fitted to rims |

from 25" up to 35" |

from 25" up to 51" |

from 25" up to 57" |

| Spin force, tons | 70 | 100 | 150 |

| Overall dimensions, mm | 2800х2800х2300 | 3820х3820х3100 | 4310х4310х3200 |

| Weight, tons | 1.7 | 1.73 | 2.9 |

3.2. A stationary OTR tire changer Press

Fixed OTR tyre changers NMZ series are analogue of TP tyre changers manufactured by Reliable Wheel Products Ltd., Canada.

Fixed OTR tyre changers NMZ series are analogue of TP tyre changers manufactured by Reliable Wheel Products Ltd., Canada.

Specification

| Model |

NMZ-200 | NMZ-300 | NMZ-400 |

| For all tyres fitted to rims |

from 25" up to 51" |

from 25" up to 57" |

from 49" up to 63" |

| Spin force, tons | 200 |

300 |

400 |

| Overall dimensions, mm | 2800х2800х2300 | 3820х3820х3100 | 4310х4310х3200 |

| Weight, tons | 13 |

18 |

22 |

You can see the description and principle of operation of the tyre changers in the video

You can see the description and principle of operation of the tyre changers in the video

3.3. A stationary OTR tire changer Press

Fixed OTR tyre changers 31 series are analogue of tyre changers manufactured by BelAZ

Specification

| Model |

31-78 | 31-16 | 31-37 |

| For all tyres fitted to rims |

from 25" up to 35" |

from 25" up to 51" |

from 49" up to 57" |

| Spin force, tons | 120 | 120 | 150 |

| Overall dimensions, mm | 3520x2580x2870 | 3520x2580x2870 | 4070x2880x3635 |

| Height over floor level, mm |

1440 | 1440 | 1785 |

| Weight, tons | 1.74 | 2.35 | 6.8 |

Delivery terms

Our company can deliver equipment to any region specified by you. Initial proposal is drafted on EXW Chelyabinsk, FOB Saint-Petersburg, Russia or FOB Vladivostok, Russia. Final proposal is drafted including transport costs to the port of arrival.We can deliver equipment to anywhere in the world.

Packing of the equipment guarantees full safety and protects against damage during transport.

All equipment is delivered with the full set of necessary instruction manuals (user`s manual, technical specification etc.) in English, Spanish or French languages.

All your requests and offers please send to e-mail to@probelaz.ru or phone us + 7 /351/ 230-39-33, 236-94-04, 773-62-11, 773-47-01

Based on this Vulcanizing Machine the delivery of full set of OTR repair equipment including all necessary equipment, instrument and expendables for repair actions is possible.

Based on this Vulcanizing Machine the delivery of full set of OTR repair equipment including all necessary equipment, instrument and expendables for repair actions is possible.  Vulcanizing System «Model 63» is for one-step repair system (using hot vulcanization technology) – analogue to Vulcanizing Machine Monaflex’s flagship system (manufactured by Monarch Vulcanizing Systems Ltd, UK).

Vulcanizing System «Model 63» is for one-step repair system (using hot vulcanization technology) – analogue to Vulcanizing Machine Monaflex’s flagship system (manufactured by Monarch Vulcanizing Systems Ltd, UK).

Vulcanizing Machine «Model 40.00» is for one-step repair system (using hot vulcanization technology) – analogue to Vulcanizing Machine Monaflex’s flagship system (manufactured by Monarch Vulcanizing Systems Ltd, UK).

Vulcanizing Machine «Model 40.00» is for one-step repair system (using hot vulcanization technology) – analogue to Vulcanizing Machine Monaflex’s flagship system (manufactured by Monarch Vulcanizing Systems Ltd, UK). Vulcanizing Machine «Model 21.00» is for one-step repair system (using hot vulcanization technology) – analogue to Vulcanizing Machine Monaflex’s flagship system (manufactured by Monarch Vulcanising Systems Ltd, UK).

Vulcanizing Machine «Model 21.00» is for one-step repair system (using hot vulcanization technology) – analogue to Vulcanizing Machine Monaflex’s flagship system (manufactured by Monarch Vulcanising Systems Ltd, UK).